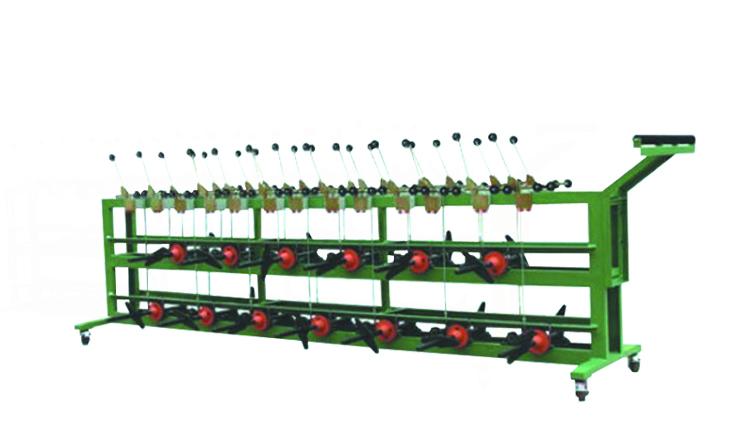

Silicone tube extruder

- The parameter values of the silicone tube extruder and are as follows: Product model JF-0904 1. Silicone tube extruder | Silicone tube extrusion machine | Silicone tube equipment | Silicone ext……

- Consultation hotline: Jack 13809267162

-

Product Details

The parameter values of the  silicone tube extruder

silicone tube extruder

and

are as follows: Product model JF-0904 1. Silicone tube extruder | Silicone tube extrusion machine | Silicone tube equipment | Silicone extruder | Silicone extrusion machine | Silicone tube extrusion machine | Silicone device Usage: Suitable for the production of silicone tubes for water dispensers, bottle tubes, color printers, side-by-side silicone ink tubes, silicone tubes, silicone strips, sealing rings, and door and window shaped strips for extrusion production. 2. Silicone tube extruder | Silicone tube press Special Wire Extruder Series 2025-02-10 17:09:56

1. Silicone Tube Extruder | Silicone Tube Extrusion Machine | Silicone Tube Equipment | Silicone Extruder | Silicone Extrusion Machine | Silicone Equipment Purpose: Suitable for producing

and

silicone tubes for water dispensers, bottle tubes, color printers, and extruding

and

silicone ink tubes, silicone tubes, silicone strips, sealing rings, and door and window shaped strips. 2. Silicone tube extruder | Silicone tube extrusion machine | Silicone tube equipment | Silicone extruder | Silicone extrusion machine | Silicone equipment features: (1) Full process control, adjustment, and monitoring of various process parameters of the production line. (2) Silicone specific screws, winding tubes, machine heads, eye molds, and supporting structures to prevent internal vulcanization. (3) Silicone dedicated self centering machine head and water-cooled automatic or manual control system. (4) Configure a precision detection feedback system to ensure accurate wire diameter and greatly reduce costs. 3. Silicone tube extruder | Silicone tube extrusion machine | Silicone tube equipment | Silicone extruder | Silicone extrusion machine | Silicone equipment process: After the silicone product is extruded by the extruder, it is suspended through a pre high temperature vulcanization drying channel to achieve pre vulcanization and rapid shaping; Then, after passing through

and

, the drying tunnel is fully vulcanized, solving the production and quality problems that traditional silicone rubber extrusion vulcanization processes cannot solve; Squeeze

and

to produce a sulfurized thin-walled tube that is very round and without any deformation; Squeeze vulcanized large-diameter silicone tubing and thick walled tubing, with no pressure marks on the surface; Squeezing

and

to produce various shaped silicone strips with complex cross-sectional shapes; Ensure precise size and shape, and can guarantee excellent extrusion vulcanization effect for various

and

soft and hard silicone rubbers with hardness ranging from 30 degrees to 70 degrees; The drying channel is made of stainless steel on both the inner and outer layers; Superior thermal insulation performance, with long

and

intervals during insulation, saving energy consumption, being clean and beautiful, and having no pollution to the product; Using specially designed quartz heating tubes High temperature and radiation interaction benefit

and

, with short vulcanization time and high thermal efficiency; After the drying oven reaches the set temperature, it will automatically switch to constant temperature control, and at this time, the

and

heaters in one area will be automatically turned off to save electricity; Can be used for producing silicone tubes, silicone strips, irregular strips, foam tubes, etc. with short vulcanization time, high efficiency in producing

and

, and an hourly output of about 60-180KG; The operation is very convenient. 4. Silicone tube extruder | Silicone tube extrusion machine | Silicone tube equipment | Silicone extruder | Silicone extrusion machine | Silicone equipment technical parameters:

model/parameters: φ 45, φ 65, φ 90 extrusion amount (KG) 50, 90, 180 line speed (M/Min) 30, 30, 30, gearbox 113, 146, 200 screw speed (rmp) 10-50 10-50 10-50 10-50 aspect ratio 12:1 12:1 12:1 main engine power (KW) 5.5, 7.5, 22 hot oven (m) 6, 10, 10, steel strip traction (MM) 100, 120, 120, drag (KW) 0.75, 1.5

,

,

,  ,

,

Previous: EL Cold Light Extruder Next: EL Cold Light Line Pasting Machine Related Products  Silicone Tube Extruder 2025-02-10

Silicone Tube Extruder 2025-02-10  EL Cold Light Extruder 2025-02-10

EL Cold Light Extruder 2025-02-10  EL Cold Light Line Pasting Machine 2025-02-10

EL Cold Light Line Pasting Machine 2025-02-10