New type of irradiated rubber wire and cable extrusion production line (granular material)

- new irradiation rubber wire and cable extrusion production line (granular material) rubber extruder, rubber machine, irradiation rubber parameter values Product model JF-02 CPE rubber wire and cable……

- Consultation hotline: Jack 13809267162

-

Product Details

new irradiation rubber wire and cable extrusion production line (granular material)

new irradiation rubber wire and cable extrusion production line (granular material)

rubber extruder, rubber machine, irradiation rubber

parameter values Product model JF-02 CPE rubber wire and cable high-speed extrusion production line I. Introduction to radiation cross-linked CPE rubber wire and cable 1.1 Introduction and use of CPE material: Chlorinated polyethylene (CPE) is an artificial synthetic rubber and the most cost-effective rubber; CPE has excellent mechanical strength and electrical insulation performance, heat aging resistance, weather aging resistance, oil resistance, and solubility resistance Radiation cured rubber extruder series 2025-02-10 17:20:55

CPE rubber wire and cable high-speed extrusion production line

I. Introduction to radiation crosslinked CPE rubber wire and cable

1.1 Introduction and use of CPE material:

Chlorinated polyethylene (CPE) is an artificial synthetic rubber and the most cost-effective rubber; CPE has excellent mechanical strength and electrical insulation properties such as

and

, heat aging resistance, weather aging resistance, oil resistance, solvent resistance, flame resistance, impact resistance, high flexibility, and excellent processability; CPE is widely used in profiles and seals; Used in the manufacturing of medium and low voltage insulation materials and sheath materials in the electrical

and

cable industry; CPE is widely used in the profile industry for hard materials, such as Dalian Shide and Wuhu Hai’s

and

spiral profiles; In the wire and cable industry, CPE is gradually replacing chloroprene rubber and chlorosulfonated polyethylene rubber with an unstoppable trend, and partially replacing natural rubber and ethylene propylene rubber with

and

Compared with chloroprene rubber, it is slightly inferior in terms of oil resistance under the premise of meeting national standards, but the prices of

and

are only 1/2-1/3 of chloroprene rubber; Compared with chlorosulfonated polyethylene rubber, all properties are equivalent, but the price is only the

and

of chlorosulfonated polyethylene rubber; Compared with natural rubber and ethylene propylene rubber, although its insulation performance is inferior, it is still an excellent material for manufacturing low voltage insulation and sheath of

and

due to its excellent flame retardancy. Especially, its low price is incomparable to ethylene propylene rubber The current situation of

and

1.2 radiation cross-linked CPE rubber wires and cables.

and

radiation cross-linked wires and cables have been widely used in China, such as overhead cables, medium and low voltage transmission cables, various electrical wiring, etc; Radiation crosslinking materials include

,

PE, EVA, PVC, and mixtures of various polyolefin materials The use of CPE rubber for radiation cross-linking of wires and cables began 10 years ago, but due to the formulation technology of materials such as

and

, wire extrusion production technology and radiation process technology have not been overcome, and industrial production still cannot be achieved in China today; At present, there is no effective solution in the field of

and

in China, and it is also difficult for industrial production Based on the known information, currently only one factory has the capacity for large-scale production.

and

produce over 10 million meters of finished cable products annually

1.3 Material formula technology and wire production and radiation process technology

produce qualified radiation cross-linked CPE rubber wire and cable products, which require three major technical supports. These three technologies are:

1.3.1 Material formula technology:

Material formula technology is the basis of radiation cross-linked CPE rubber wire and cable products. Currently, the technology is completely based on cheap CPE as the substrate, combined with various auxiliary materials to improve the material and process performance of

”

. After reasonable mixing, it is made into granular product rubber particles, which is completely different from traditional methods. The production method of

and

for rubber materials is a new method for producing rubber materials. The production process of rubber materials is as follows:

and

Formula raw materials – Kneading and mixing – Granulation – Rubber particles – Packaging finished products

and

1.3.2. Wire extrusion production technology

and

Good CPE materials cannot be obtained without good wire extrusion production technology In order to improve the quality and efficiency of wire production, the production of radiation

and

cross-linked CPE rubber wire and cable is completely different from the traditional rubber wire production method. The production process of the new method and the traditional method is as follows:

and

new method:

and

rubber particles – wire extrusion molding – cooling molding – wire winding

and

traditional methods:

and

rubber strips – wire extrusion molding – wire vulcanization – cooling molding – wire winding

and

. Due to the use of particle feeding and the absence of wires in the new method, Sulfurization greatly improves production efficiency and reduces product defect rates The radiation process technology of

and

is an indispensable and important factor in radiation crosslinked CPE rubber wire and cable products. This technology is the final link to ensure high efficiency, high quality, low price, and low

and

consumption. Without this technology, qualified radiation crosslinked CPE rubber wire and cable products cannot be obtained The total production process of

and

1.3.4 radiation crosslinking CPE rubber wire and cable is as follows:

and

formula raw materials ->kneading and mixing ->rubber particle granulation ->semi-finished rubber particle products ->rubber particle feeding ->wire extrusion of

and

forming ->cooling and shaping ->wire winding (semi-finished product) ->accelerator radiation crosslinking ->CPE rubber wire and cable products

and

. The above methods are completely the same as the simplest PVC production except for the accelerator radiation crosslinking production process. In other words, radiation crosslinking is used to manufacture

and

radiation crosslinked CPE. Rubber wire and cable are produced by adding a radiation cross-linking process on the basis of PVC wire, which can obtain high-quality rubber wire and cable 1.3.4. Cost Analysis and Production Equipment

1.3.4.1. Rubber Material Cost: Due to advances in formulation technology, the cost of rubber materials is comparable to that of ordinary 105 ℃ PVC materials. In other words, there is no significant cost increase compared to ordinary

105 ℃ PVC materials, which is about 13000 yuan/ton;

1.3.4.2. Production cost of wire extrusion: The production cost of radiation cross-linked wire extrusion is equivalent to that of ordinary PVC wire extrusion, without any apparent cost increase;

1.3.4.3. Radiation cross-linking production cost: The production cost of radiation cross-linking varies for different specifications of wire. For the planned production of

and

specifications, the production cost of radiation cross-linking is approximately 0.02-0.5 yuan/meter; Overall cost, the total production cost of radiation cross-linked wires is like adding 0.02-0.5 yuan/meter of irradiation fee to ordinary 105 ℃

and

PVC wires, and the cost increase can be said to be negligible 1.3.4.4. Production equipment cost: Compared with ordinary PVC wire production lines, the equipment investment is relatively higher due to stricter production process requirements. However, the CPE rubber wire and cable extrusion production line launched by Dongguan

and

Jingfeng Electrical Machinery Co., Ltd. is relatively cheap and does not require a large amount of capital to purchase large equipment and boilers.

and

also do not need to occupy a large number of factories, and the production of rubber materials and wire extrusion also meets national environmental protection requirements.

II The production of irradiated rubber extrusion equipment products

and

mainly produces medium and low voltage electrical wiring, power transmission and distribution cables, and other products. The product types include:

and

2.1. American standard cables

and

such as HPN SJOW SOOW series wires for UL CSA products. This part is mainly exported to the United States, Canada, or matched with domestic electrical

and

manufacturers exporting to the above-mentioned countries. Its market is very large, with tens of millions or even billions of meters of market every year; 2.2. European standard cables such as VDE products’ HO5RN, HO7RN, HO3RN, HO5RR and other series of wires are mainly exported to EU countries or matched with domestic electrical manufacturers exporting to EU

and

alliance countries. Their market is also large, with tens of millions or even hundreds of millions of meters per year;

2.3. National standard cables

include YZ, YZW and other series of wires for national standard products, which are mainly used domestically and are matched with domestic household appliances such as Midea, Gree, Chunlan, Hai

and various electric tools. Their market is also very large The CPE rubber extrusion equipment of Dongguan Jingfeng Electrical Machinery Co., Ltd. has undergone years of innovation, improvement, and transformation practice. The equipment manufacturing technology is mature, the performance is stable, and the production speed of

and

has been greatly improved, winning good reviews from customers. The

and

CPE irradiation crosslinked rubber wire and cable production line (rubber extruder, rubber extrusion equipment) is a product developed by Dongguan Jingfeng Electrical Machinery Co., Ltd. in 2009. The

and

patent numbers ZL201020001065.5, ZL201020001066. X, ZL201820180779.3 have been explored and developed for more than 10 years. After more than 10 years of exploration and research and development, the equipment has been put into the market, making the production of

and

rubber wire no longer unattainable. It does not require a large amount of capital to purchase large equipment and boilers, nor does it need to occupy a large number of factories. Only a small amount of capital investment is needed, just like producing

and

PVC wire, which can produce high-quality and environmentally friendly products. The manufacturing cost of the product is reduced by more than 25% compared to traditional steam pipeline vulcanization, and the product meets UL, VDE, CCC

and

certifications. In short, radiation crosslinked CPE rubber wires and cables can achieve high-quality and high selling price rubber wires (cables) with much higher performance than ordinary 105 ℃ PVC wires through radiation crosslinking, without significantly increasing material and production costs.

and

only increase irradiation costs

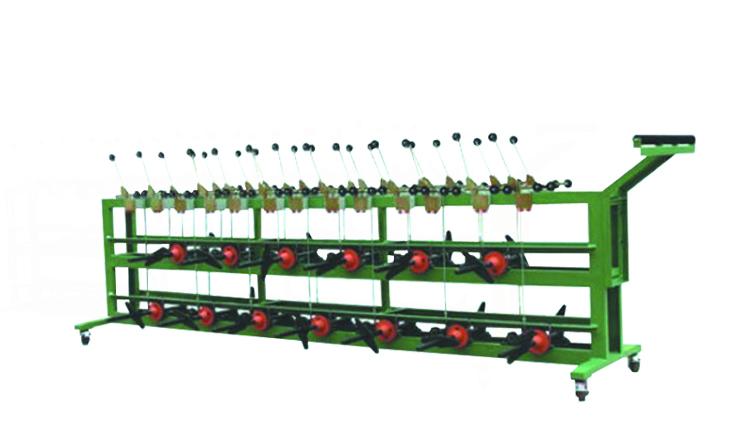

III Equipment composition:

and

. Cable laying: 630 double head cable laying, 800-1250 cantilever cable laying.

and

powder passing machine,

and

. Extrusion host or vertical injection molding machine (model determined by wire selection).

and

rubber extrusion host.

and

. Head: adjustable self core head.

and

mold temperature machine.

and

laser caliper.

and

water tank.

and

cremation experiment. Machine

traction machine

oil passing machine

wire storage rack

wire winding machine: double axis wire winding machine, 800-1250 cantilever wire winding machine

The finished product diameter is Φ 0.5-3mm, Φ 1.0-5mm, Φ 3-10mm, Φ 3-10mm, and Φ 5-15mm. The diameter of the finished product is Φ 1.5-6mm, Φ 2.0-10mm, Φ 5-13mm, and Φ 8-20mm. The diameter of the screw is Φ 70mm, Φ 80mm, Φ 90mm, and Φ 100mm. The length to diameter ratio of the screw is 16:1/18:1, 16:1/18:1, 16:1/18:1, 16:1/18:1. The extrusion rate is 150Kg/h, 200Kg/h, 250Kg/h, 280Kg/h, 360Kg/h, the main engine power is 30kw, 45kw, 55kw, 55kw, 95kw, and the wire speed is up to 300m/min according to the wire diameter. The diameter of the winding reel is Φ 500-630mm, and the diameter is Φ 500-630mm. The Rubber wire and cable extrusion production line (sheet material) related products  new irradiation rubber wire and cable extrusion production line (granular material) 2025-02-10

new irradiation rubber wire and cable extrusion production line (granular material) 2025-02-10  new irradiation rubber wire and cable extrusion production line (sheet material) 2025-02-10

new irradiation rubber wire and cable extrusion production line (sheet material) 2025-02-10