Cable equipment, rubber wire, fiber optic production line

- cable equipment, fiber optic production line, and parameter values, product model JF-001. Equipment purpose: This production line is mainly used for the production of tight fitting optical fibers, s……

- Consultation hotline: Jack 13809267162

-

Product Details

cable equipment, fiber optic production line,

cable equipment, fiber optic production line,

and

parameter values, product model JF-001. Equipment purpose: This production line is mainly used for the production of tight fitting optical fibers, single and dual core flexible optical cables, and FTTH terminal optical cables. The extruded sheath has a uniform and smooth diameter, high speed, and low additional fiber loss. This production line is suitable for extruding materials such as LSZH (low smoke halogen-free material), PVC, etc. 2、 Equipment composition: 1. Dual fiber amplifier Fiber optic cable equipment series 2025-02-10 16:39:05

I. Equipment purpose: The production line of

and

is mainly used for the production of tight fitting optical fibers, single and dual core flexible optical cables, and FTTH terminal optical cables. The extruded sheath has a uniform and smooth diameter, high speed, and low additional fiber loss. This production line is suitable for extruding materials such as LSZH (low smoke halogen-free material), PVC, etc. 2. Equipment composition:

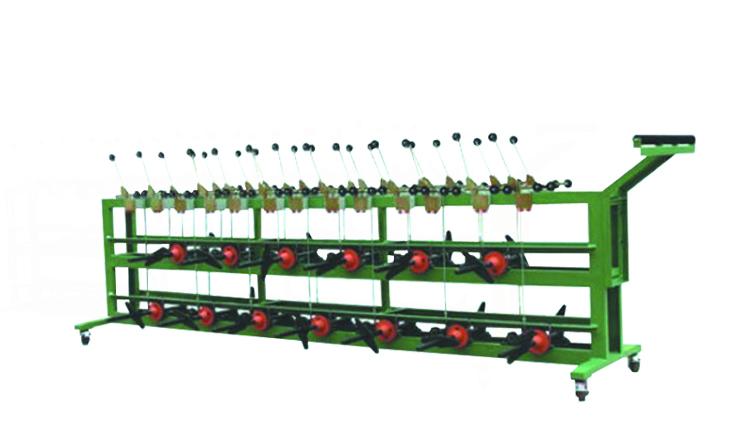

1. Dual fiber optic pay off rack:

2. Dual tightly wrapped fiber pay off rack:

3. JF45/plastic extruder:

4. Warm water tank:

5. Warm water tank:

6. Cold water tank:

7. Cold water tank:

“

8. Blow dryer:

9. Bidirectional diameter measuring instrument

and

10. 630 single wheel traction machine

and

11. Horizontal wire storage device

and

12. Double disc winding device

and

13. Meter counting device

and

14. Inkjet printing machine (optional)

and

15. Electrical control system

and

3. The operation of the entire production line of

and

adopts a reliable Siemens series 10.4-inch color touch screen. The control adopts Siemens P7-200 series PLC, In order to improve the stability of the product line diameter and the accuracy of speed regulation, the host adopts a Euro 591 DC controller, the temperature is controlled by a Japanese RKC temperature controller and solid-state relay, and the traction is controlled by Delta servo control, which enhances the synchronization and stability performance of the host and traction. The bidirectional caliper and PLC use communication to display on the touch screen. Other AC frequency converters use Yaskawa A1000 series high-performance frequency converters, the servo system uses Taiwan’s Delta AC servo, and other low-voltage electrical appliances use Chint or joint venture brands. On the touch screen, parameters such as production line speed, host speed, operating current, meter length, cable outer diameter, etc. can be displayed. The production line also has complete fault alarms and maintenance guidance instructions